The global industrial revolution demands the integration of cutting-edge material handling technologies. In 2025, the conveyor systems market demonstrates rapid growth—according to analytics forecasts, the value of industrial automation will reach $307.7 billion by 2030, growing at 9.3% annually. At the heart of this transformation lie advanced conveyor solutions—technologies that combine high productivity, sanitary safety, and energy efficiency. A leading innovator in this field is Wire Belt Company, whose stainless steel metal conveyor belts with open-mesh structure—particularly Flat-Flex®, Eye-Flex®, and Compact-Grid®—have set new standards for the food processing, automotive, and electronics manufacturing industries.

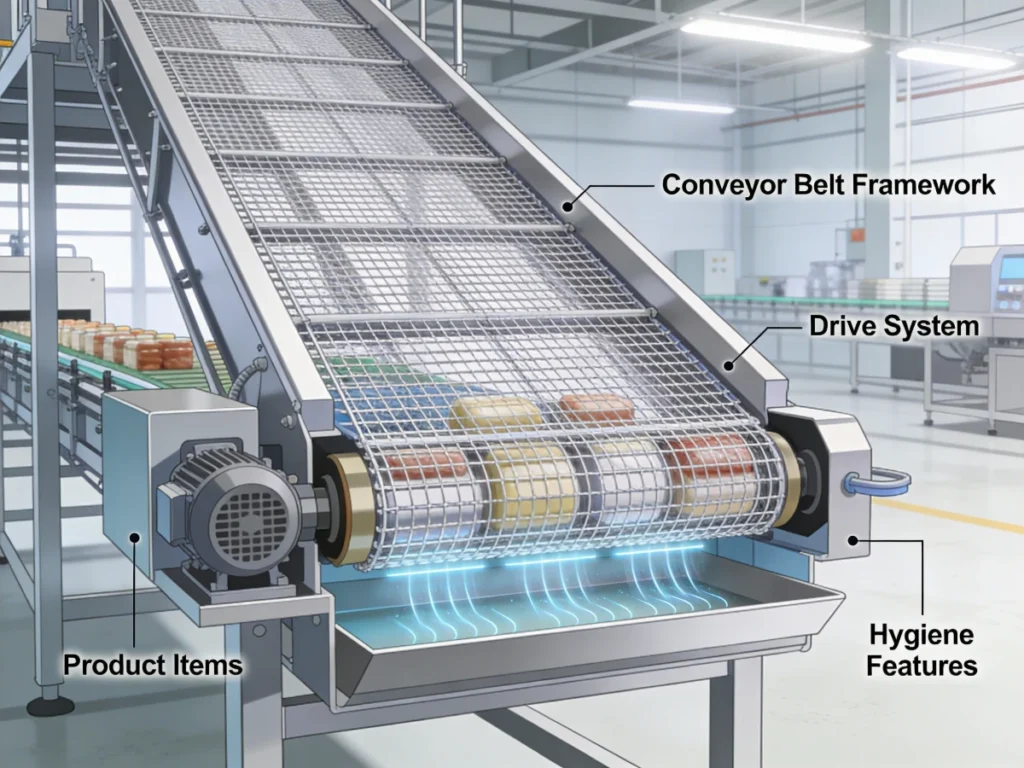

Modern industrial conveyors are more than simple transport lines. They represent intelligent systems that integrate IoT sensors for predictive maintenance, ensure HACCP and FDA compliance, and reduce energy consumption by 15-20% through lightweight materials and optimized design. Wire Belt Company, with over 60 years of experience, offers specialized conveyor belts and maintenance tools designed to improve efficiency, maintain hygiene standards, and enable precise product handling in food processing, electronics, and automotive sectors.

Technological Evolution of Conveyor Systems: From Mechanics to Smart Solutions

Metal Conveyor Belts with Open Structure: Engineering Excellence

Metal mesh conveyor belts have become a revolutionary solution for industries where hygiene, temperature resistance, and air permeability are critical. Unlike traditional plastic or rubber belts, the wire mesh belt conveyor solutions from Wire Belt Company are manufactured from high-quality stainless steel types SS304, SS316L, and special alloys, providing exceptional strength, corrosion resistance, and the ability to withstand temperatures from -200°C to +400°C.

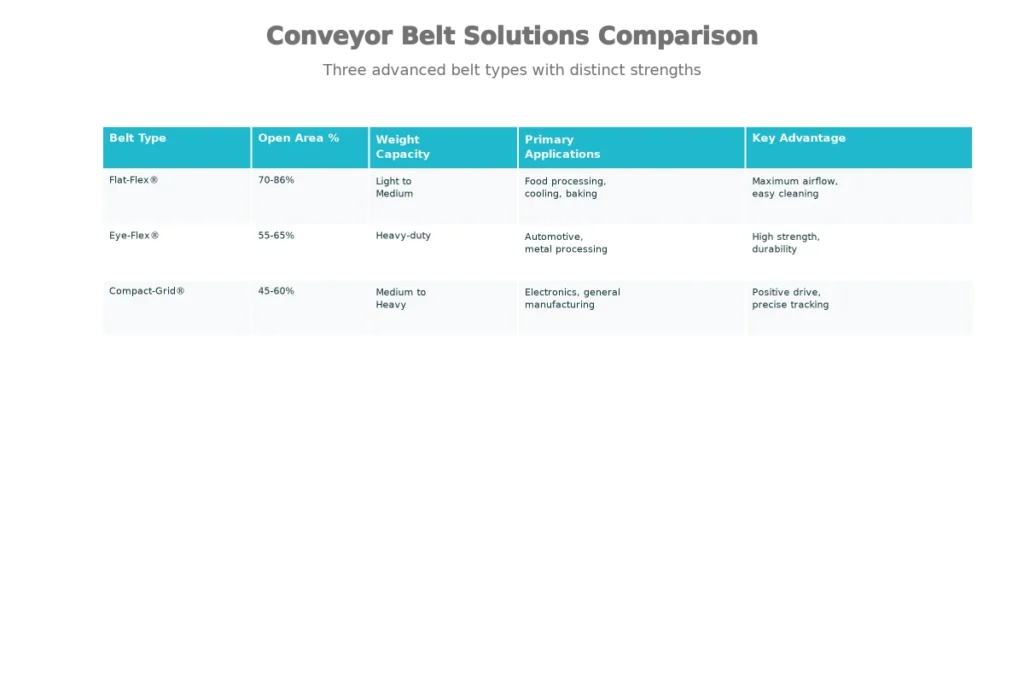

A key advantage of the open-mesh structure is maximum air circulation. The Flat-Flex® belts feature open area up to 86%, enabling efficient cooling of baked goods, freezing products, or rinsing components without obstruction of air and water flows. This not only accelerates technological processes by 30% but also reduces energy costs, as the lighter belt mass requires less thermal or cooling energy.

Eye-Flex®—a heavy-duty belt type—is engineered for extreme conditions in metalworking and automotive manufacturing, where high strength and the ability to transport heavy components at elevated temperatures are essential. Meanwhile, Compact-Grid® provides positive drive without slippage, critical for precise component positioning in electronics manufacturing and automated robotic production lines.

Sanitary Requirements and Compliance with International Standards

Food safety is an absolute priority in modern manufacturing. HACCP (Hazard Analysis and Critical Control Points) systems require that all components in contact with food products comply with strict sanitary standards. Wire Belt Company’s metal conveyor belts are designed with these requirements in mind:

- Non-porous Surface: Stainless steel has no pores, preventing bacterial accumulation, unlike plastic or fabric materials.

- Clean-in-Place (CIP) Compatibility: The open structure allows high-temperature pressure washing without belt removal, reducing downtime by 40%.

- FDA and USDA Certification: Materials comply with U.S. Food and Drug Administration and Department of Agriculture requirements.

- Minimal Gap Spaces: The DiaCrimp® technology design ensures tight spiral bonding, eliminating spaces where product residues could accumulate.

In 2024, over 65% of food industry companies implemented modular conveyor systems to meet growing sanitary requirements and improve production flexibility.

Industrial Applications of Advanced Conveyor Solutions

Food Processing Industry: From Bakeries to Freezing

The food processing sector is the largest consumer of metal conveyor belts. Applications span the entire production chain:

- Baking and Roasting: Belts withstand temperatures exceeding 300°C in industrial ovens, ensuring even baking through open structure.

- Freezing and Cooling: Open area up to 86% enables rapid product temperature reduction while preserving texture and quality. A real-world case study shows 30% reduction in cooling time after Flat-Flex® implementation.

- Glazing and Coating: Eye-Flex® is used for transporting products through chocolate or glaze coating zones, where resistance to sticky substances is important.

- Washing and Drainage: The open structure ensures effective water and detergent removal, particularly important when processing vegetables and fruits.

According to research, metal conveyor belts improve food production hygiene standards by at least 10-fold compared to traditional solutions.

Automotive Industry: Precision and Durability

Automobile manufacturing requires conveyors capable of withstanding significant loads and ensuring precise component positioning. Wire Belt conveyor systems are used at various production stages:

- Body Component Transportation: Heavy-duty Eye-Flex® belts move large metal panels through welding and painting zones.

- Heat Treatment of Components: Belts withstand temperatures up to 1150°C in hardening and annealing processes for metal parts.

- Assembly Lines: Compact-Grid® positive drive provides synchronization with robotic pick-and-place systems, improving assembly precision by 25%.

Automation based on advanced conveyor systems increases production speed by 42%—according to North American Robotics, in the first quarter of 2025, automotive manufacturers ordered 42% more industrial robots compared to the previous year.

Electronics Manufacturing: Precision and Cleanliness

Electronics manufacturing demands the highest standards of cleanliness and precision. Conveyors for the electronics industry must provide:

- Antistatic Properties: Special coatings and materials prevent static electricity accumulation, which can damage sensitive components.

- Minimal Vibration: Wire Belt’s Flat Seat® technology reduces vibration by 60%, critical for precise assembly of microcomponents.

- Heat Resistance: During soldering and sealing processes, belts withstand temperatures up to 260°C.

Implementing machine vision and AI algorithms in conveyor systems for sorting electronic components has achieved 98% accuracy, processing over 600 items with minimal computational overhead.

Intelligent Maintenance and Predictive Diagnostics

IoT and Industry 4.0: Next-Generation Conveyors

Integrating Internet of Things (IoT) and artificial intelligence is radically transforming conveyor system operation and maintenance. Modern monitoring systems include:

- Real-Time Vibration and Temperature Analysis: Sensors detect anomalies at early stages, preventing 70% of potential failures.

- Predictive Maintenance: Machine learning algorithms analyze historical data to forecast component replacement needs, reducing unplanned downtime by 30%.

- Digital Twins: Virtual conveyor models simulate operational changes without production stoppage. According to Gartner, by 2025, 70% of large industrial companies will use digital twins for equipment optimization.

- Automated Decision-Making: AI-based systems can automatically adjust conveyor speed, flow direction, and sorting modes based on current loading.

According to market research, IoT-integrated conveyors improve operational efficiency up to 30%, confirmed by reports from the Conveyor Equipment Manufacturers Association.

Energy Efficiency and Sustainable Development

Environmental responsibility is becoming a key factor in industrial equipment selection. Advanced conveyor solutions contribute to reducing environmental footprint:

- Lightweight Materials: Using reduced-weight metal belts cuts energy consumption by 15-20% compared to traditional rubber belts.

- Low-Friction Coatings: Special surfaces reduce movement resistance, allowing energy savings up to 20%.

- Regenerative Drives: Systems with recovered energy convert braking kinetic energy back into electricity.

- Eco-Friendly Materials: Manufacturing belts from recycled stainless steel reduces CO₂ emissions by 40%.

Companies implementing energy-efficient conveyors report total operational cost reductions of 25-50% within the first two years of operation.

Wire Belt Company Innovations: Competitive Advantages

Positive Drive Technology and Tracking Precision

One of Wire Belt Company’s key achievements is developing the positive drive system used in Compact-Grid® belts. Unlike friction drives where belt slippage is possible, positive drive with sprockets ensures:

- Zero Slippage: ±1 mm positioning accuracy, critical for operation with pick-and-place robotic systems.

- Load Stability: Even when transporting heavy components, the belt maintains travel trajectory.

- Extended Durability: Absence of friction wear extends belt service life to 5 years.

Specialized Conveyors and Maintenance Tools

Wire Belt offers not just belts, but a complete solution package, including:

- Ladder-Flex™ Conveyors: Designed for sorting, merging, or dividing products in motion, necessary to prevent sticking during coating or glazing.

- Spiral Conveyors: Compact systems for vertical transport, saving up to 60% of production floor space.

- Connection Tools: A unique splicing system allows belt joining in less than 30 seconds without specialized equipment.

- Cleaning Devices: Specialized brushes and debris removal systems integrated directly into conveyor structure.

Thanks to modular design, Wire Belt conveyors easily scale and adapt to changing production needs, ensuring flexibility and rapid integration.

Trends and Future of Conveyor Technology 2025-2030

Autonomous and Robotic Systems

Combining conveyors with autonomous robots creates new possibilities for fully automated production facilities:

- Robotic Sorting: Amazon Robotics and DHL use conveyors with integrated robotic manipulators, increasing order processing speed by 45%.

- Automatic Loading Systems: Robots load and unload conveyors without human involvement, reducing workplace injuries by 25%.

- Collaborative Robots (Cobots): In the first quarter of 2025, cobots represented 11.6% of all industrial robots installed in North America, especially in food processing.

According to World Economic Forum predictions, by 2030 automation will create 78 million new jobs globally, replacing 92 million outdated positions.

Artificial Intelligence and Machine Learning

AI is transforming conveyor management approaches:

- Dynamic Route Optimization: Systems automatically adjust material flows based on current loading.

- Automatic Defect Detection: YOLOv7 algorithms achieve 98% accuracy in detecting belt soiling and damage.

- Real-Time Inventory Management: AI integration with warehouse management systems reduces picking time by 63%.

The market for AI-driven conveyor systems is expected to grow to $9.2 billion by 2025, with emphasis on logistics and e-commerce.

Sustainable Development and Carbon-Neutral Solutions

By 2035, the industry aims to achieve full autonomy with AI predictive maintenance and carbon-neutral warehouses:

- Solar Conveyors: Systems with photovoltaic panels integrated into structure are being developed.

- Composite Materials: Using biopolymers and recycled plastic for component manufacturing.

- ML-Based Load Optimization: Algorithms distribute weight to reduce energy consumption by 20%.

Practical Tips for Selection and Implementation

Criteria for Conveyor System Selection

When choosing a conveyor solution, consider:

- Product Type and Weight: For heavy components—Eye-Flex®; for light food products—Flat-Flex®.

- Temperature Range: Determine maximum and minimum process temperatures.

- Sanitary Requirements: For food and pharmaceutical industries, FDA/USDA certification is mandatory.

- Open Area: For processes with intensive air circulation, minimum 70% open area is required.

- Drive Type: Positive drive for precision, friction drive for simple applications.

FAQ

Metal stainless steel belts withstand extreme temperatures (up to +400°C), don’t absorb moisture and bacteria, provide better hygiene, and have 3-5 times longer service life than plastic alternatives.

Use belts with FDA/USDA certification, minimize gap spaces, apply CIP-compatible designs, and regularly conduct cleaning validation according to HACCP protocols.

Cost depends on specifications, but average ROI is 30-200% during the first year through reduced downtime, energy consumption, and maintenance costs.

By detecting problems early, predictive maintenance reduces unplanned downtime by 30%, cuts repair costs by 25%, and extends equipment service life by 20%.

Conclusion: Investing in the Future of Manufacturing

Advanced conveyor solutions from Wire Belt Company represent a synthesis of engineering excellence, innovative materials, and intelligent technologies. In 2025, when industrial automation grows at 10.8% annually, implementing high-quality metal conveyor belts becomes not just a competitive advantage, but a necessity for ensuring operational efficiency, meeting sanitary standards, and promoting sustainable development.

Integrating wire mesh belt conveyor solutions from Wire Belt Company with technologies such as Flat-Flex®, Eye-Flex®, and Compact-Grid® enables food processing, automotive, and electronics manufacturing enterprises to achieve:

- 30-45% productivity increase through automation and flow optimization.

- 15-20% energy consumption reduction by using lightweight, low-friction materials.

- 30% fewer unplanned downtime through predictive maintenance.

- 10-fold improvement in sanitary standards through CIP-compatible designs and FDA/USDA certification.

In a world where every second of downtime costs thousands of dollars, and food product safety determines company reputation, choosing the right conveyor solution becomes a strategic decision. Wire Belt Company, with over sixty years of experience, innovative materials, and global support network, remains the leader trusted by world-leading manufacturers.

Ready to transform your production? Visit Wire Belt Company to consult with experts and select the optimal solution for your industry.

Отримуйте оперативні новини від Village Life – підписуйтеся на наш Telegram-канал – https://t.me/villagelifebiz